Overview of Liquid Silicone Rubber (LSR)

Composition and Properties of LSR

Liquid Silicone Rubber (LSR) is a silicone-based polymer, blended with elements like silicon, oxygen, carbon, and hydrogen. Enhanced with a platinum catalyst, LSR is versatile, suitable for a range of applications from medical devices to automotive parts. Its unique composition ensures durability and adaptability in various environments.

LSR is renowned for its heat resistance, enduring extreme temperatures without losing integrity. It’s highly flexible, ideal for complex designs, and chemically stable, resisting many chemicals and bodily fluids. These properties make LSR components indispensable in sectors requiring reliability and precision.

Applications of LSR in Various Industries

Liquid Silicone Rubber’s (LSR) application in the medical industry is pivotal, especially in manufacturing surgical instruments and medical devices that contact human tissue. Its biocompatibility ensures safety and reliability. In the automotive sector, LSR’s heat resistance and durability are crucial for producing vibration-resistant sealed housings and various liquid silicone rubber parts together, enhancing vehicle performance and safety.

LSR in Electronics and Consumer Products

In electronics, LSR excels due to its temperature resistance and insulation, essential for components like connectors and housings. Its versatility extends to consumer goods, where its non-toxic, hypoallergenic nature benefits various products. In pet supplies, LSR is used for durable chew toys and bowls, while in kitchenware, it’s ideal for heat-resistant baking molds and utensils. For baby products, like teething rings, and in adult products, the LSR material’s safety and softness are paramount, showcasing its wide-ranging utility.

Importance of High-Quality in LSR Injection Molding

Quality Standards in LSR Molding

Precision in LSR parts is crucial, particularly for medical devices and automotive seals. High-quality standards ensure performance and safety, especially when parts are exposed to body fluids or extreme temperatures. Rigorous testing and strict adherence to manufacturing protocols are essential to maintain these standards, ensuring reliability in critical applications.

Challenges in Maintaining Quality

Key challenges in LSR molding include curing and material shrinkage for tight tolerances, controlling mold temperature for superior surface finishes, and ensuring the precision of the molding machine. These factors are vital for consistent quality, affecting everything from surgical instruments to electronic components, where precision and durability are non-negotiable.

Benefits of High-Quality LSR Parts

High-quality LSR parts offer durability and reliable performance under extreme conditions. This is vital in sectors where parts must resist high pressure and harsh environments. Investing in quality leads to long-term cost-effectiveness, with fewer failures and longer lifespans, enhancing overall efficiency in both production and application phases.

Key Factors Influencing Quality in LSR Injection Molding

Material Selection for Optimal Results

Characteristics of High-Quality Silicone Rubber

High-quality silicone rubber, crucial in LSR molding, comes in various forms, each tailored for specific applications. Food-Grade Silicone is ideal for kitchenware due to its safety and heat resistance. Anti-static Silicone, used in electronic components, prevents static build-up. Medical-Grade Silicone, known for its biocompatibility, is essential in surgical instruments and medical devices. Color-Changing Silicone, often found in consumer goods, responds to environmental changes, enhancing user interaction.

Conductive Silicone serves in electronic parts requiring electrical conductivity. High-Temperature Silicone, used in automotive gaskets and seals, withstands extreme heat. Flame Retardant Silicone is crucial for safety in electrical applications, where fire resistance is essential. Low-Temperature Silicone remains flexible in cold environments, suitable for outdoor applications. Each type is engineered for optimal performance in its respective field, ensuring reliability and functionality.

Supplier Selection and Material Consistency

Selecting a reliable supplier like MoldTechPro is essential for ensuring the consistency of silicone rubber, impacting diverse applications. Consistent material quality is key in sectors like consumer electronics, where Conductive Silicone’s uniformity affects device performance, and in household goods, where consistent High-Temperature Silicone ensures safety and durability in kitchenware. Similarly, for outdoor products, consistent Low-Temperature Silicone is necessary to maintain flexibility in varying climates. The right supplier choice directly affects the quality and reliability of the final LSR products, from household items to advanced electronic gadgets.

Mold Design and Its Impact on Product Quality

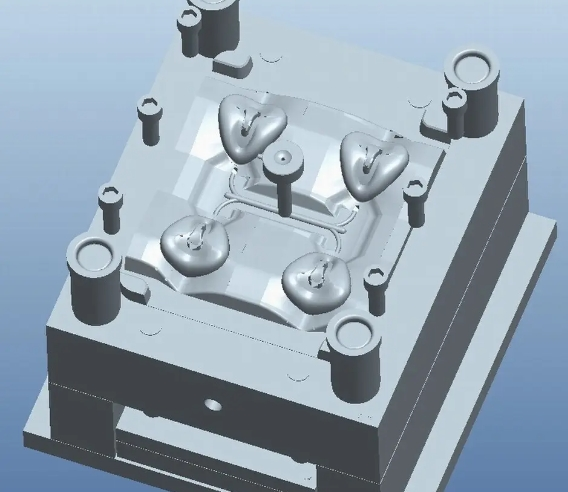

Advanced Mold Design Techniques

Many Silicone moulding manufacturers utilize computer-aided design (CAD) tools to optimize mold designs and check integrated components in LSR injection molding. Simulation software plays a significant role in determining the most efficient and effective processing regimen, helping to fully optimize the Liquid Injection Molding (LIM) process and avoid pitfalls. Thermal imaging technology is also employed to pinpoint potential production issues, aiding in the prevention of molding defects and design irregularities

Challenges in Mold Making and Material Considerations

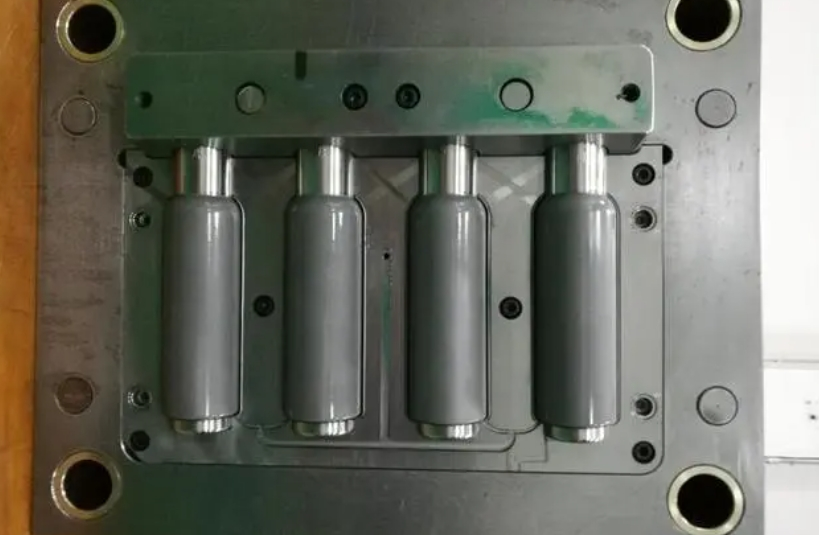

Precision in mold making is essential for LSR production, with challenges like material shrinkage and demolding intricacies. Silicone’s elasticity requires careful handling during ejection from molds, often necessitating multiple plates and automated robotic systems with grippers and air for damage-free part removal. Accurate mold design is crucial to minimize shrinkage and ensure uniformity in parts, impacting everything from electronic connectors to kitchenware. In high-stakes applications like surgical instruments, mold precision is non-negotiable for ensuring product safety and performance.

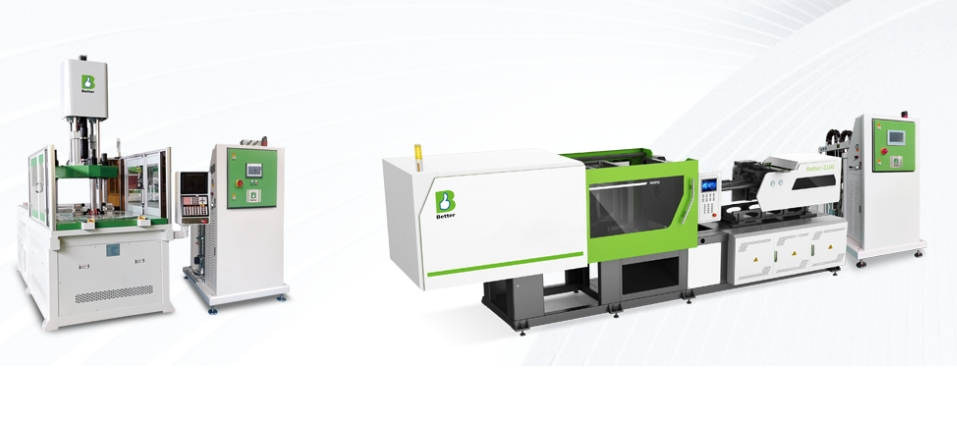

The role of LSR Injection Molding Machine

Selecting the Right Injection Molding Machine

Choosing the right LSR injection molding machine is critical, focusing on pressure control and temperature management for optimal results. Machines tailored for LSR, featuring specific elements like accurate metering units and precision injectors, are crucial for manufacturing high-quality LSR products across various applications.

Calibration of Equipment

Calibration of LSR injection molding equipment is essential to ensure the machine meets production standards. Proper calibration, as per manufacturer guidelines, guarantees that the molding process adheres to the necessary quality and consistency, crucial for a wide range of LSR products.

LSR Molding Process

The Injection Molding Cycle Explained

The Injection Molding Cycle Explained

The LSR injection molding cycle involves closing the mold, injecting LSR, the curing process, and opening the mold for part removal. This cycle is crucial for producing consistent, high-quality LSR parts suitable for a range of applications.

Key Process Parameters of Liquid Injection Molding Process and Their Impact

Control Methods for LSR Injection Molding Temperature:

Heater Temperature: The heater heats the liquid silicone rubber, typically set between 320°F to 356°F.

Injection Head Temperature: This is the temperature of LSR as it enters the mold, usually set between 338°F to 374°F.

Mold Surface Temperature: Generally set between 122°F to 176°F, this temperature is critical for the mold’s surface.

Appropriate Temperature Range for LSR Molding:

The suitable temperature range for LSR injection molding is typically between 302°F to 392°F. This range varies based on the LSR type, hardness, and color. Harder silicone rubbers require higher temperatures, while softer ones need lower temperatures. Light-colored LSRs are molded at lower temperatures compared to dark-colored ones.

Impact of Temperature and Pressure on Product Performance and Appearance::

Temperature changes significantly influence LSR’s physical and aesthetic qualities. High temperatures may reduce elasticity and low temperatures can lead to increased hardness. Additionally, injection pressure, ranging from 200 to 1,000 psi, is a key factor. This pressure range ensures proper material flow and molding, affecting everything from dimensional accuracy to the occurrence of defects like bubbles or voids.

Minimizing Defects Through Process Control

Effective process control is key to minimizing defects in LSR molding. Regular monitoring and adjustments based on real-time data are crucial for maintaining consistent quality and reducing wastage, thereby enhancing overall production efficiency.

Quality Control and Testing in LSR Injection Molding

H3: Implementing Rigorous Quality Control Measures

In-Process Quality Checks: Quality in LSR molding begins early in the product life cycle, incorporating tools like blueprints, control plans, and technical problem-solving methods. These checks are vital for identifying issues early and maintaining product integrity throughout the manufacturing process.

Post-Molding Quality Assurance: Following the molding process, each product undergoes extensive inspections to ensure compliance with specific standards. This phase, crucial for identifying any necessary post molding secondary operations, assesses the products based on their functional features and performance characteristics. Defects are carefully analyzed, aiding in refining manufacturing processes and planning for any additional finishing steps. This rigorous quality assurance guarantees that each LSR part fulfills its intended application with high precision and reliability.

H3: Advanced Testing Methods forLSR Products

Mechanical and Chemical Testing: LSR products are subjected to tests like Shore hardness, tensile strength, and pressure/leak testing, ensuring they meet control plan requirements and maintain consistent quality.

Ensuring Compliance with Industry Standards: The process includes establishing critical parameters and features in alignment with customer expectations. Dimensional measurements and visual inspections complement each other to ensure the LSR parts meet required standards and tolerances, which may differ from those in plastics and metals.

This approach to quality control and testing in LSR injection molding emphasizes the importance of thorough planning, continuous monitoring, and rigorous testing to ensure that the final products are of the highest quality and meet industry standards.

Conclusion and Future Trends

Summarizing Key Takeaways

The LSR injection molding process demands precise control over factors like temperature, pressure, and mold design to produce high-quality parts. Rigorous quality control measures, both in-process and post-molding, are essential to ensure products meet the required standards.

Future Innovations in LSR Injection Molding

Advancements in LSR molding are expected to focus on enhancing material properties, automation, and sustainability. Companies like MoldTechPro can play a pivotal role in this evolution, offering solutions to streamline the molding process, improve precision, and reduce defects, ultimately leading to more efficient and cost-effective production.

FAQs

Common Defects in LSR Injection Molding: Defects like air entrapment and inconsistent curing can be prevented through precise temperature control and adequate pressure application.

Impact of Silicone Rubber Quality: The quality of silicone rubber directly affects the durability, elasticity, and overall performance of the final product.

Key Considerations in Mold Design: Precision, material compatibility, and the ability to handle complex geometries are crucial.

Temperature and Pressure Effects: These factors significantly influence the molding process, affecting the curing of silicone, the quality of the final product, and the occurrence of defects.