Introduction

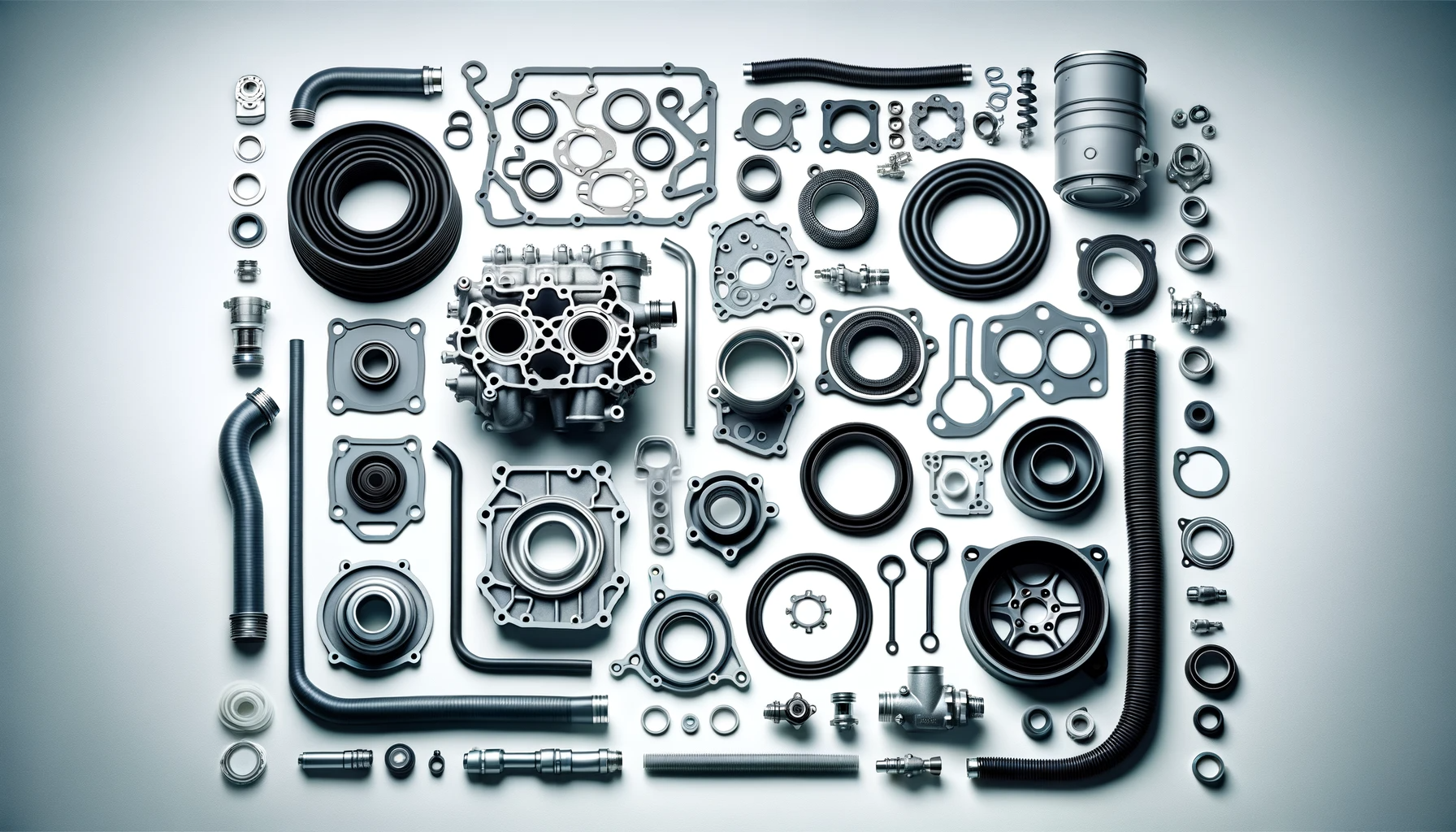

In the rapidly advancing automotive industry, Liquid Silicone Rubber (LSR) plays a crucial role, known for its exceptional durability high strength and flexibility. This blog aims to delve into the extensive applications and benefits of LSR in automotive manufacturing. We explore how LSR’s unique properties cater to the evolving needs of modern vehicles, from enhancing engine performance to improving safety features. Join us as we uncover the pivotal role of LSR in driving innovation in the automotive sector.

The Edge of LSR – Benefits for the Automotive Industry

Key Advantages in Automotive Manufacturing

Liquid Silicone Rubber (LSR) distinguishes itself in the automotive sector with unmatched benefits, surpassing traditional materials like thermoplastic elastomers. Notably, its high temperature resistance and chemical resistance are crucial for automotive applications such as spark plug boots and ignition cables. LSR ensures that silicone rubber products retain their integrity and performance, even in extreme temperatures and challenging environmental conditions found in engine compartments.

Superiority Over Other Materials

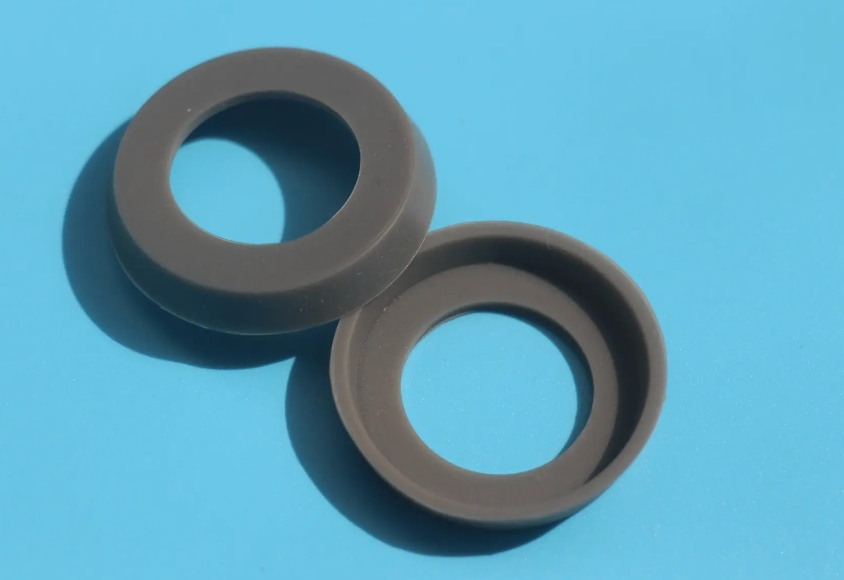

Compared to other rubbers, LSR exhibits a lower coefficient of friction and enhanced oil bleeding resistance, crucial for producing efficient parts like O-rings and gaskets. This is especially advantageous in electric and hybrid vehicles, where reliability and fuel efficiency are key. Furthermore, LSR’s high dielectric strength makes it the material of choice for automotive electronics, safeguarding sensitive electronic components.

LSR as an Ideal Material for Automotive Applications

Unmatched Material Properties for the Automotive Sector

Liquid Silicone Rubber (LSR) has become a favored material in the automotive industry due to its unique blend of properties that are essential for a wide range of automotive components. The exceptional heat resistance and chemical resistance of LSR make it suitable for challenging environments, particularly in engine compartments where high temperatures and exposure to various chemicals are common. Additionally, its flexibility and durability are crucial in maintaining the integrity of various parts under stress and environmental elements.

Enhancing Vehicle Performance and Safety

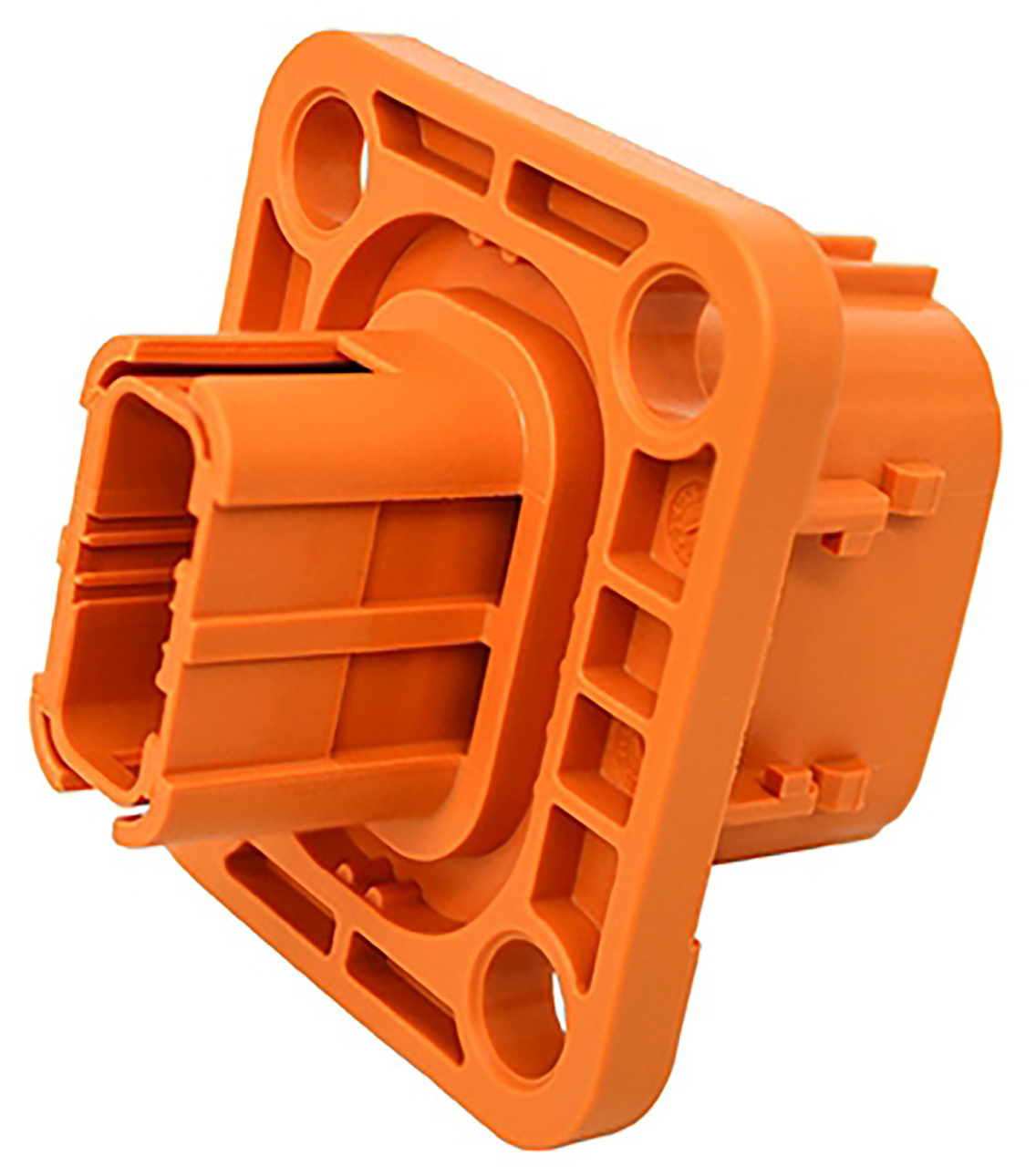

The high dielectric strength and low coefficient of friction of LSR contribute significantly to the overall safety and performance of vehicles. These properties are particularly beneficial in the manufacturing of electronic components and connectors, where LSR ensures reliable insulation and protection against electrical failures. Furthermore, its capacity to withstand extreme temperatures and environmental conditions enhances the longevity and reliability of parts, contributing to the overall safety and efficiency of automobiles.

Case Study: LSR in Spark Plug Boots and Ignition Cables

One notable application of LSR in the automotive industry is in the production of spark plug boots and ignition cables. These components require materials that can withstand high temperatures and resist electrical interference. LSR’s high temperature resistance and high dielectric strength make it an ideal choice, ensuring efficient operation and longevity of these components. Manufacturers have reported a significant improvement in performance and reliability since switching to LSR for these applications.

Case Study: LSR in Seals and Gaskets for Electric and Hybrid Vehicles

Another exemplary case of LSR’s effectiveness is its use in seals and gaskets for electric and hybrid vehicles. These vehicles demand materials that offer high efficiency and resistance to a range of environmental stresses. LSR’s unique properties, including its chemical resistance and durability, make it an ideal material for creating seals and gaskets that can maintain their integrity over time, contributing to the overall fuel efficiency and reliability of these eco-friendly vehicles.

Innovative LSR Applications in Automotive Parts

The Advancement of Two-shot LSR Injection Molding

The automotive industry has seen a significant leap forward with the adoption of two-shot LSR injection molding, a process that combines the versatility of LSR with advanced manufacturing techniques. This method allows for the creation of complex, multi-material components in a single production step, enhancing efficiency and reducing production time. The use of this technology in automotive manufacturing signifies a shift towards more sophisticated and integrated component design.

Case Study 1: Two-shot Connectors with Radial Seals:One remarkable application of this technology is in the production of two-shot connectors with radial seals. These connectors are crucial for maintaining secure and reliable electrical connections in the various components of automotive systems, including safety and infotainment. The radial seals, made from LSR, offer superior sealing properties, essential for protecting against environmental elements and ensuring long-term functionality. The integration of LSR in these connectors demonstrates its ability to enhance the reliability and durability of automotive electronics.

Case Study 2: Two-shot Components with Flange Seals:Another groundbreaking automotive application is the use of two-shot LSR injection molding in creating components with flange seals. These components are integral in systems where leak-proof sealing is critical, such as in fuel or fluid transport within the vehicle. The flange seals, crafted from LSR, provide excellent bonding strength and chemical resistance, ensuring that they withstand the harsh conditions typically encountered in the engine compartment. This application highlights LSR’s capacity to withstand extreme temperatures and harsh chemical environments, making it a highly suitable material for demanding automotive applications.

LSR in Electric and Hybrid Vehicles

Liquid Silicone Rubber (LSR) is revolutionizing electric and hybrid vehicle technology with its unique applications. In electric vehicles, LSR enhances battery safety and performance, thanks to its exceptional heat resistance and electrical insulation. For hybrid models, LSR’s durability and chemical resistance make it ideal for sensor and connector applications, balancing the demands of electric and combustion systems. This advanced material supports the automotive industry’s shift towards sustainable, high-performing electric and hybrid vehicles, playing a crucial role in the development of eco-friendly transportation technologies.

Quality Control and Industry Standards in LSR Manufacturing

Upholding High-Quality Standards in LSR Outputs

In the production of Liquid Silicone Rubber (LSR) parts for the automotive industry, maintaining high quality is paramount. This involves rigorous quality control processes at every stage of the manufacturing cycle. From the selection of raw materials to the final inspection of finished parts, each step is crucial in ensuring that LSR components meet the stringent requirements of the automotive sector. Advanced testing methods, such as stress testing and thermal resistance evaluations, are employed to guarantee that the parts can withstand the extreme conditions they will face in vehicles.

The Role of Industry Standards and Certifications

Adhering to industry standards and certifications is vital in LSR part production. Compliance with standards such as ISO 9001 for quality management and ISO/TS 16949 specific to automotive quality management, ensures consistency and reliability in the manufacturing process. These certifications serve as a benchmark for manufacturers, signaling their commitment to producing high-quality, dependable silicone products. Moreover, adhering to these standards is often a prerequisite for suppliers looking to collaborate with major automotive manufacturers, as it demonstrates a dedication to excellence and reliability in product performance.

Ensuring Safety and Performance

Quality control and adherence to industry standards are not just about meeting contractual obligations; they are essential for ensuring the safety and performance of automotive vehicles. High-quality LSR parts contribute to the overall reliability and efficiency of vehicles, playing a critical role in areas such as engine performance, safety systems, and electronic components. Therefore, manufacturers must prioritize these aspects to uphold the integrity and reputation of the automotive industry.

Trends and Future Outlook for LSR in the Automotive Industry

In the automotive industry, the trend towards using Liquid Silicone Rubber (LSR) is gaining momentum, particularly for applications like connector seals and wiper blades, where its high strength and versatility are advantageous. LSR’s evolving role in auto industry is marked by innovations in silicone materials, expanding its use in various automotive components. Looking ahead, LSR is expected to be integral in advancing automotive technologies, especially in autonomous vehicles. Its adaptability and potential for sustainable, efficient applications position it as a key material for future developments in the automotive sector.

Environmental Considerations and Sustainability

The use of Liquid Silicone Rubber (LSR) in the automotive industry aligns with environmental sustainability goals. LSR’s eco-friendly nature is enhanced by its longevity and ability to withstand extreme conditions, reducing the need for frequent replacements. Progressive strategies for recycling LSR and effective waste management practices are being developed, further minimizing the environmental impact. These initiatives highlight the commitment to sustainable practices in automotive manufacturing, making LSR a preferred raw material used in eco-conscious production.

Final Thoughts

In conclusion, Liquid Silicone Rubber (LSR) has significantly influenced automotive manufacturing, offering unparalleled benefits in terms of durability, versatility, and sustainability. Its role is continually evolving, promising even greater advancements in automotive technologies. As a specialized producer of silicone mold products, MoldTechPro stands at the forefront of this evolution, offering one-stop service solutions that combine quality with competitive pricing. Their expertise underscores the bright future of LSR in automotive manufacturing, showcasing a commitment to innovation and excellence in this dynamic field. If you have any questions, come and consult MoldTechPro!