Introduction

Quality assurance in nylon injection parts manufacturing is critical, directly affecting the durability and performance of the injection molded products. This process, which utilizes nylon – a plastic material known for its moisture absorption properties – requires a high degree of precision to ensure top-quality outcomes. The role of quality assurance is integral, impacting not only the individual parts but also the overall reliability and functionality of the end products.

Advanced quality control strategies in this domain involve meticulous mold design, stringent raw material selection, and continuous monitoring throughout the production process. Utilizing statistical process control along with a robust quality management system is essential for maintaining high standards. These advanced techniques enhance manufacturing efficiency and product quality, ensuring that the final nylon injection molded parts meet the stringent requirements of various industries and customer expectations. The commitment to quality in the plastic injection molding process underscores the importance of these advanced strategies in maintaining industry standards.

Understanding Nylon Injection Molding

Basics of Nylon Material

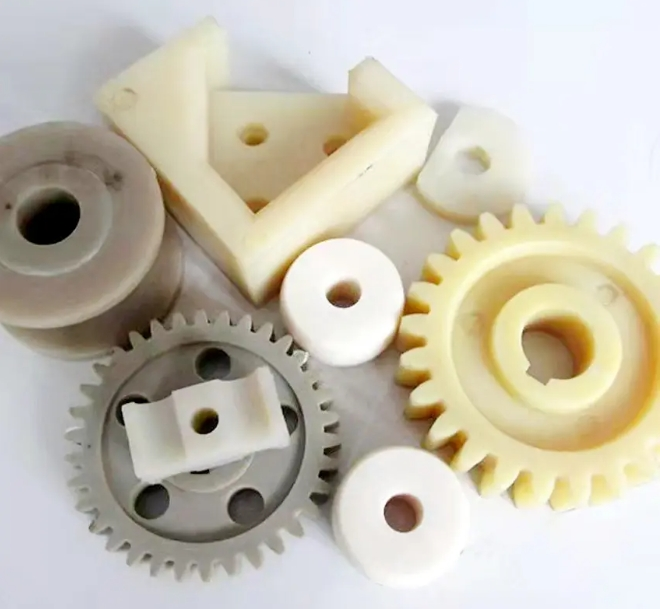

Nylon, a robust and versatile plastic material, is renowned for its strength, thermal stability, and resistance to wear and chemicals. Key in plastic injection molding, nylon’s ability to absorb moisture can influence its properties and the quality of injection molded parts. This characteristic necessitates careful material selection and handling to maintain the integrity of nylon injection molded products.

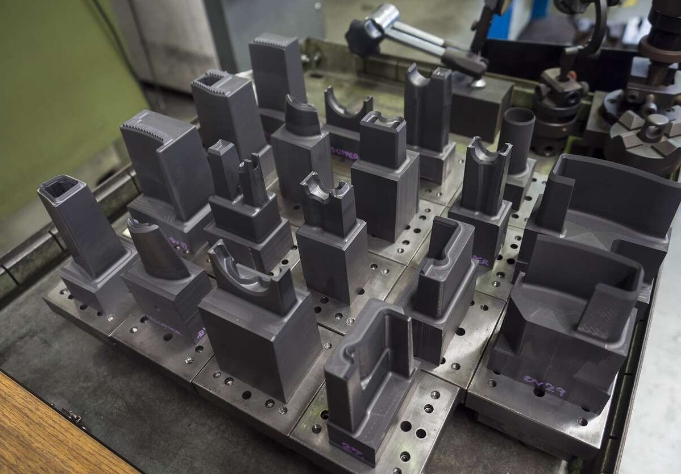

The Injection Molding Process for Nylon Parts

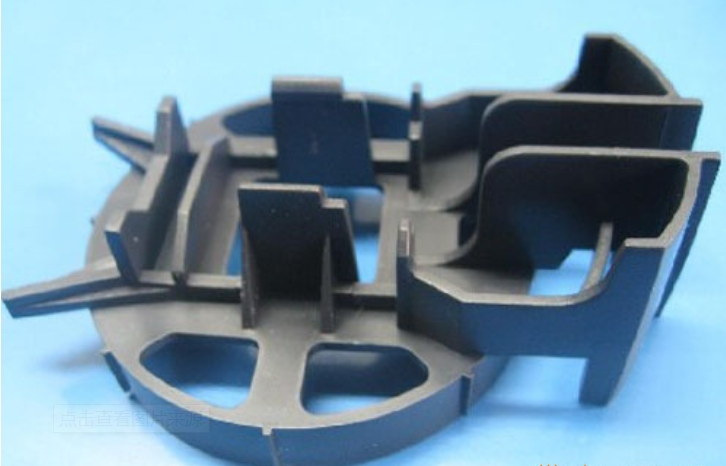

The injection molding process for nylon parts is a critical aspect of manufacturing high-quality products. The process initiates by melting nylon, then injecting it into a meticulously crafted mold at high pressure, necessitating precise temperature and pressure regulation for uniform quality.Factors like mold design, wall thickness, and gate placement play significant roles in the outcome. The mold cavity is filled with the molten nylon, which solidifies upon cooling, forming the intended component.Ensuring optimal conditions throughout this process is essential to prevent defects like sink marks or incomplete filling, underscoring the importance of a well-managed injection molding process in achieving high-quality nylon parts.

Challenges in Nylon Parts Quality Assurance

Common Quality Issues in Nylon Injection Parts

Quality assurance in nylon injection molding faces unique challenges, primarily due to the nature of the nylon material and the intricacies of the injection molding process. Common quality issues include warping, which is often a result of uneven cooling or material thickness variations. Sink marks, another frequent defect, occur due to inadequate cooling or insufficient pressure controls during the molding process. Moisture absorption in nylon can lead to poor surface finish and affect the dimensional stability of the injection molded part, making moisture control a critical aspect. Additionally, improper gate placement can result in incomplete filling, leading to weak or defective parts. Addressing these challenges requires a meticulous approach to the manufacturing process, from material selection to precise control of molding parameters.

The Impact of Defects on Performance and Reliability

Defects in nylon injection molded parts can significantly impact their performance and reliability. Warping and dimensional inaccuracies can lead to assembly issues and poor fit in final products, while surface imperfections and structural weaknesses can compromise the part’s functional integrity. In sectors demanding high precision and endurance, like automotive and medical device production, these flaws can lead to critical problems.Therefore, ensuring high-quality output in nylon injection molding is not just about aesthetics but is crucial for maintaining the functionality, safety, and reliability of the final products.

Advanced Quality Assurance Techniques

Implementing In-line Monitoring Systems

In the realm of nylon injection molding, the implementation of in-line monitoring systems represents a significant leap in quality assurance. These systems provide real-time data on critical parameters like temperature, pressure, and cycle time during the injection molding process. By continuously monitoring these variables, manufacturers can detect and address potential quality issues early, reducing the likelihood of defects in the final nylon injection molded parts. This proactive approach is essential for maintaining high quality, especially in complex parts where precision is crucial. The use of in-line monitoring enhances the production process’s overall efficiency, optimizing resource utilization and reducing material waste.

Precision Measurement Tools for Quality Control

Precision measurement tools are indispensable in the quality control process for nylon injection molded parts. These tools, ranging from calipers to advanced 3D scanning systems, allow for accurate measurement of the dimensions, surface finish, and other critical attributes of the molded parts. By employing these tools, manufacturers can ensure that each part adheres to the stringent specifications required by the industry and customers. The use of precision measurement in quality control not only helps in detecting deviations from desired standards but also aids in continuous improvement of the injection molding process. This dedication to exactness highlights the significance of sophisticated quality assurance methods in producing top-notch nylon injection components.

Material Quality and Pre-processing

Assessing Raw Material Quality

The foundation of high-quality nylon injection molded parts lies in the quality of the raw materials used. Assessing the quality of nylon plastic material is a critical step, involving thorough checks for consistency, purity, and appropriate physical properties. Factors like the material’s viscosity, color, and moisture content are crucial indicators of its suitability for the injection molding process. Ensuring the raw materials meet the required standards is essential, as any compromise in material quality can lead to defects in the final product, affecting its performance and durability. Evaluating the quality of materials is a crucial part of the quality control process, paving the way for successful manufacturing results.

Importance of Material Drying and Pre-processing

Given nylon’s tendency to absorb moisture, material drying and pre-processing are essential steps in the nylon injection molding process. Proper drying of nylon material before it enters the injection molding machines is crucial to prevent quality issues such as poor surface finish, warping, and incomplete filling. The pre-processing stage also involves conditioning the material to the right temperature and viscosity, which are key to achieving optimal flow and filling characteristics during the injection molding process. By investing time and resources in proper material drying and pre-processing, manufacturers can significantly enhance the quality and consistency of their nylon injection molded parts.

Process Control and Optimization

Controlling Injection Molding Parameters

Effective control of injection molding parameters is crucial for the production of high-quality nylon parts. Critical parameters, including temperature, pressure, and speed of injection, need careful regulation to maintain the structural integrity and exactness of the molded components. For nylon, which is sensitive to variations in processing conditions, maintaining consistent temperature control is essential to prevent defects like warping or sink marks. Pressure controls are equally important to ensure complete filling of the mold and to maintain the desired part density and strength. Adjusting these parameters for each production run, considering the specific properties of nylon material, is fundamental to achieving optimal results in the injection molding process.

Machine Learning in Process Optimization

The integration of machine learning in the injection molding process represents a significant advancement in manufacturing technology. By analyzing large datasets from the production process, machine learning algorithms can identify patterns and predict optimal molding conditions for different nylon parts. This approach allows for real-time adjustments and process optimization, enhancing the efficiency and quality of the production. Machine learning tools can also aid in predictive maintenance of injection molding machines, anticipating potential issues before they impact product quality. The application of this advanced technology in process optimization underscores the evolving nature of the injection molding industry and its move towards smarter, data-driven manufacturing practices.

Employee Training and Involvement

A skilled workforce is crucial in nylon injection molding, ensuring quality assurance through their expertise in handling complex processes and materials. Their ability to identify and address potential issues is vital for maintaining the high-quality standards of injection molded parts. Continuous training programs are essential, keeping the workforce abreast of the latest industry practices and technological advancements. This ongoing education fosters a culture of quality and continuous improvement, crucial for producing superior nylon injection molded parts.

Advanced Testing Methods

Non-Destructive Testing Techniques

Non-Destructive Testing (NDT) techniques are vital in the quality assurance of nylon injection molded parts. These methods allow for the inspection of parts without causing damage, making them ideal for continuous quality control. Techniques like ultrasonic testing, X-ray imaging, and visual inspection are used to detect internal and surface defects, ensuring the structural integrity and quality of the nylon parts. NDT is particularly useful in identifying issues like cracks, voids, or inclusions that are not visible to the naked eye but can significantly impact the part’s performance.

Accelerated Life Testing for Durability Assessment

Accelerated Life Testing (ALT) is another advanced method used to assess the durability and lifespan of nylon injection molded parts. By subjecting the parts to accelerated stress conditions, such as high temperatures and pressure, ALT simulates the long-term effects of operating environments in a shorter time frame. This testing provides valuable insights into how the parts will perform over their expected life cycle and helps in identifying potential failure modes. Employing ALT in the testing process ensures that the nylon parts not only meet current quality standards but are also reliable and durable over time.

End-to-End Quality Management Systems

Integrating Quality Assurance Throughout the Production Cycle

In nylon injection molding, integrating quality assurance across the production cycle is essential. This comprehensive approach ensures quality from raw material selection to the final product, with consistent monitoring and control at each stage. It helps identify and address issues early, guaranteeing the consistent quality of nylon injection molded parts.

ISO Standards and Compliance

Adhering to ISO standards, such as ISO 9001, is crucial for quality management in nylon injection molding. These standards provide a framework for efficient, well-documented processes and continuous improvement. Compliance not only signifies quality commitment but also enhances process reliability and efficiency, fostering a culture of excellence.

Supplier Quality Management

Collaborating with Suppliers for Quality Raw Materials

Effective supplier quality management is crucial in ensuring the high standards of nylon injection molding. Collaborating closely with suppliers helps in securing quality raw materials, which is fundamental for producing superior nylon injection molded parts. This partnership involves clear communication of material specifications and quality expectations. Regular interactions and sharing of performance data ensure that the suppliers are aligned with the manufacturing standards and requirements. Such collaborations are essential in maintaining a consistent supply of high-grade nylon that meets the specific needs of the injection molding process.

Supplier Audits and Certification

Conducting supplier audits and insisting on certifications are key aspects of supplier quality management. These evaluations scrutinize the supplier’s capability to adhere to established quality norms and regulatory stipulations.They provide an opportunity to review and evaluate the supplier’s production processes, quality control measures, and supply chain management practices. Certifications like ISO standards serve as a benchmark for quality and reliability, ensuring that suppliers are committed to maintaining high standards. Regular audits and requiring certifications are proactive steps towards building a reliable and quality-focused supply chain, crucial for the success of nylon injection molding projects.

Conclusion

The essence of quality in nylon injection molding lies in meticulous quality assurance, advanced technologies, and skilled craftsmanship. This approach ensures the production of superior nylon injection molded parts, meeting high industry standards and customer expectations.

For professional nylon injection molding, MoldTechPro is the go-to choice. Embodying precision and excellence, MoldTechPro stands as a beacon of quality in the nylon injection molding industry.